Product Specification

Splice format: Ends opposed.

Applications: Filament winding, pultrusion, weaving.

Yarns: Carbon fibre, glass fibre, aramid, Panox, synthetic C.F.

Yarn counts:100 tex to 15000 tex

Twist: Zero or low twist yarns and tows.

Model 701 for composites

Please see the new model here

Lighter, more capable – Airbond’s latest splicer for composites.

Airbond has already shown the way in the glass and carbon fibre business, with its class-leading 110, 113 and 114 splicers. Now our latest patented technology is set to transform the business. The 701 moves standards forward, in a big way.

The 701 is even simpler and more versatile than our old ones, joining a huge range of counts in modern fibres.

And it’s lighter, handier and quicker to maintain. The actual splicer body is protected from wear and tear, safe inside an impact-resistant ABS shell.

And, like other splicers in the Airbond range, the 701 is rugged, reliable, and simple to maintain.

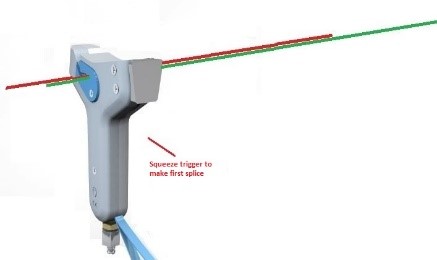

Splicer Threading

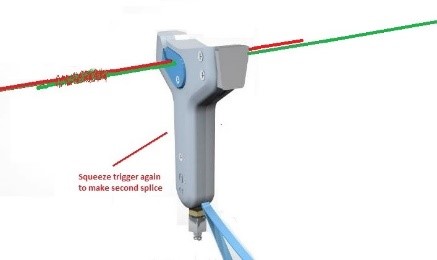

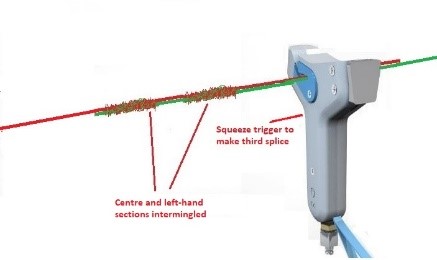

The Model 701 has been designed to splice heavy-count yarns in materials such as glass and carbon. Airbond research has shown that standard splicers – which typically make joints of around 30 mm in length – produce splices which are weak. Heavy-count yarns demand longer splices, typically up to 150 mm for 4800 tex.

After the triple-splice has been completed, trim off the waste ends with a scissors.

| Carbon | 40psi | 3 bar approx. |

| Glass / acrylic | 80 psi | 5 bar approx. |

| Nylon / polyester | 90 psi | 6 bar approx. |

Interested in the Product? Would like to find out more?