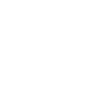

Welcome to Airbond Splicers UK

Experts in the science of splicing

Winner of the Queen's Award for Enterprise 2019

Improve Efficency, Reduce Waste, Make Savings...

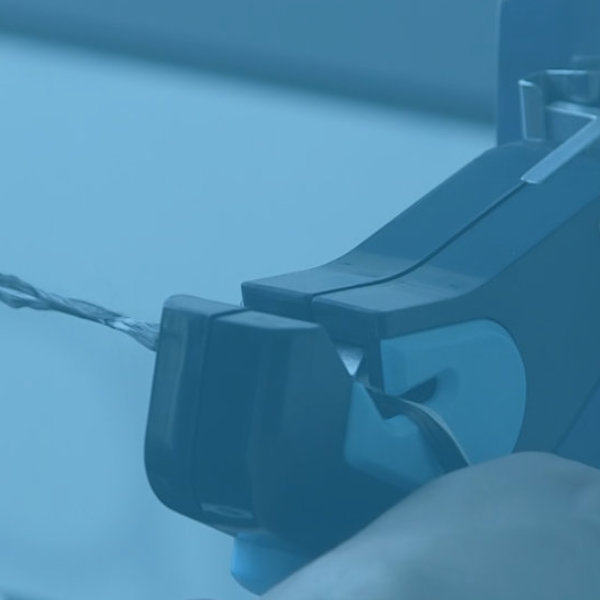

Airbond Popular Splicers

Model 131

Manufactured using completely new techniques, the 131 is similar in size and shape to the 101, but is a radical advance...

Read more →

Model 701

The Airbond Model 701 is a light, user- friendly tool, designed principally for the composites market. Matching the performance...

Read more →

Model 133

The 133 is the latest development of the splicing principles established long ago by the Airbond Models 101 and 103...

Read more →

Model 135

The Airbond Model 135 continues Airbond’s programme of continuous innovation. Functioning in exactly the same way...

Read more →

Recent News

Click here to access the 2024 Product Leaflet We’re thrilled to announce the launch of Airbond’s new product catalo …

The team at Airbond have been chosen to win the Made in Wales Manufacturing Innovation Award. The company was selec …

Composites fibre and textiles splicing experts, Airbond, has increased the limits of normal splicers by a factor of …

About Airbond

Airbond has an innovation culture; in 2019 we were awarded the UK’s coveted Queen’s Award for Industry. Uniquely for the industry, we keep developing new, cutting-edge designs for splicers. New Airbond products will keep coming, always effective, simple, and strong.